Does your condenser or heat exchanger have any of these symptoms:

- High steam turbine backpressure

- Poor thermal performance

- Tube fouling issues (scaling, biofouling, corrosion, etc.)

- Debris issues

Does your power plant:

- Burn more fuel than expected?

- Have higher than expected emissions?

- Have to de-rate to clean debris or "shoot" your condenser?

Ask us how the TAPROGGE System can improve your condenser performance.

Contact us TODAY to get back on track!

Online Condenser Tube Cleaning Systems (CTCS)

The performance of a condenser or heat exchanger can be measured by how well the system transfers heat.

Microfouling layers in the tubes significantly reduce the efficiency of the condenser or heat exchanger.

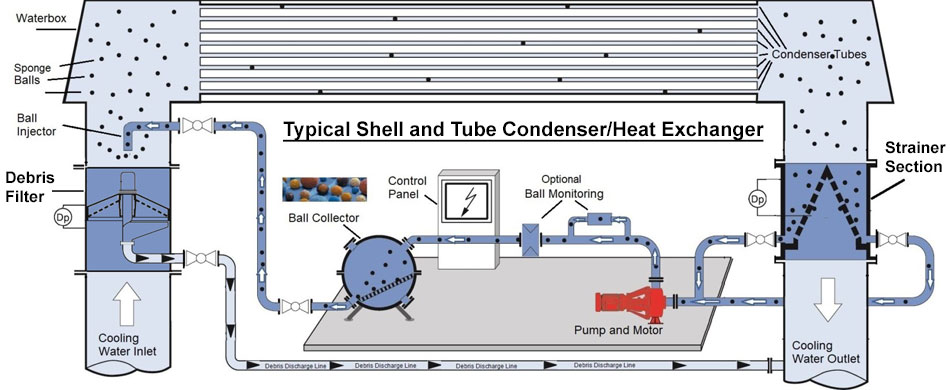

The TAPROGGE Online CTCS continuously cleans the tubes of a condenser or heat exchanger ensuring that the system is always operating efficiently.

The TAPROGGE System can:

- Increase cleanliness factor

- Reduce turbine/condenser backpressure (HgA)

- Increase unit output (MW)

- Reduce fuel costs ($/kWh)

- Reduce CO2 emissions

- Reduce unit heat rate (Btu/kWh) / Improve generating unit efficiency

- Reduce / eliminate unscheduled unit outages / derates due to micro and macrofouling issues (capacity factor)

Call us today and regain MW's lost to inefficiency!

High Performance Debris Filters

Problems in cooling water circuits are caused not only by the microfouling in the tubes of condensers or heat exchangers but also by debris (macrofouling) that is being circulated in the cooling water medium or that bypasses the prescreening equipment and reaches the condenser.

This macrofouling can plug or block tubes, leading to reduced efficiency.

The tube sheet and tubes plugged or blocked by the macrofouling then become susceptible to corrosion that could lead to tube leaks.

In cases of extreme debris loading the condenser may even need to be taken out of service and cleaned leading to reduced unit availability.

The TAPROGGE High Performance Debris Filter solves these problems!

Get in touch with us today and get the reliability and availability you've been worrying about!

We wrote the book on mechanical online Condenser Tube Cleaning

&

High Performance Debris Filter Systems.

Taprogge America Corporation (Formerly Amertap) is the Taprogge GmbH subsidiary responsible for the

North, Central & South American, Caribbean, and Israel markets.

Contact us today to learn how we can help you improve the performance of your condenser or heat exchanger.

TAPROGGE High Performance Debris Filter System

We continue to set the world technological standard for condenser efficiency through the use of our TAPROGGE High Performance Debris Filter System (DFS).

By installing the DFS at the inlet, any debris larger than 5mm is prevented from ever reaching the condenser or heat exchanger.

The DFS is self cleaning and the debris is simply rerouted downstream of the condenser. Backwash events are initiated by Differential Pressure (DP) set points, programmable time intervals, or manually.

This results in reduced pressure losses across the tubesheet created by debris, and the prevention of erosion corrosion of the tubesheet and tubes caused by debris impingement.

In cases of severe debris loading there will be no more need to derate the generating unit due to poor condenser performance due to debris or in order to manually clean the condenser.

"The TAPROGGE System"

Taprogge invented online Condenser Tube Cleaning Systems (CTCS) in 1953 and has been setting the world standard ever since.

Taprogge CTCS utilizes high quality TAPROGGE Brand cleaning balls to continuously clean the condenser tubes while the generating unit is online.

Through the use of specially designed abrasive cleaning balls, which we developed after years of research & field tests, even hard and stubborn tube fouling such as calcium carbonate or manganese can be effectively cleaned from the tube surface!

This continuous cleaning effect allows the condenser to operate at its maximum efficiency and has been proven to provide and maintain 1-3% improvements in heat rate efficiency.

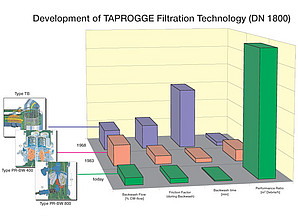

With the microfouling issues taken care of via the CTCS, Taprogge's commitment to complete efficiency led to the development of the pressure relieved backwash (PR-BW) high performance debris filter system to prevent macro fouling and debris from damaging or reducing the performance of the condenser.

With the unrivaled success of the CTCSs, TAPROGGE set it's sights on solving the next big issue for our clients worldwide:

Self Cleaning Debris Filters!

Top-Level Performance

- The Top-Level Performance graph above shows the enormous performance potential of the PR-BW 800 that stands without parallel the world over. The filter has been designed for maximum debris discharge capacity.

- Perfect filter pressure-relieved backwash (PR-BW) utilizing a multi chamber system

- Due to its enormous performance ratio (debris discharge / time) the installation of a PR-BW 800 renders the further operation or installation of an upstream travelling band screen unnecessary in many places.

- Low operational cost by small backwash water quantity, low pressure loss and little driving power

Next Steps...

Contact Us!

New, Retrofit, Service Support, Spare Parts, Training, Consulting.

We can help you achieve excellence in your reliability, availability, efficiency, performance, and environmental programs.