Our Story

Let's go back in time. Way, way back before the internet.

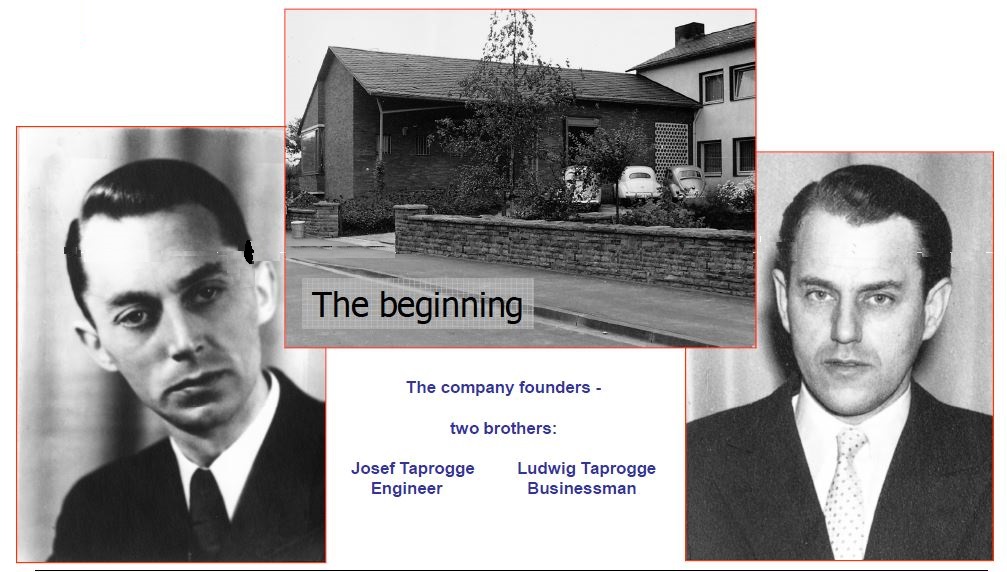

In the late 1940's an Engineer in Germany at Essen Kupferdreh Power Station, Josef Taprogge , was tasked with manually cleaning condenser tubes. A job EVERYBODY wanted! (not really).

He thought "There's gotta be a better way...". Sadly, there wasn't a better way.

So he decided to put his education and inventiveness to work and Voila!, came up with the idea that forever revolutionized how Shell and Tube condensers were cleaned and maintained. CLEANING BALLS! Who Knew?

And, believe it or not, that's how it all began over 60 years ago.

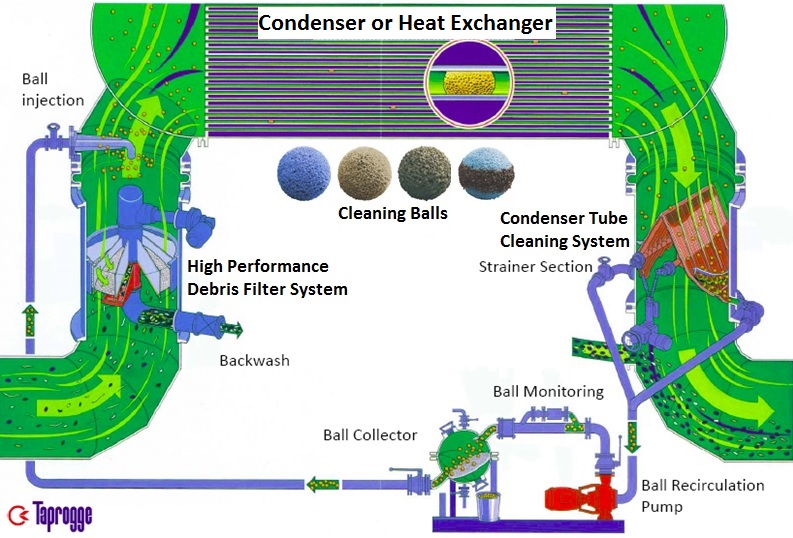

Here's how it works:

- An Online Condenser Tube Cleaning System (CTCS), circulates cleaning balls through the condenser tubes while the generating unit is in operation to offset different types of micro-fouling.

- The resulting effect of the cleaning balls ensures the condenser tubes remain free of micro-fouling, offering the maximum heat transfer at all times.

- The typical improvement in heat rate is between 1 – 3% for base loaded plants.

It became recognized worldwide as: "The TAPROGGE System"

In the USA it's simply known as: "The AMERTAP System".

Meet the Team

Some of the people responsible for the success of Taprogge America and YOUR system.

(You'll meet the rest of the team in your interactions with us!)

Steve Gillen

Managing Director

Vito Mennuti

VP Service & Systems Betterment

John Panarese

National Sales Manager

USA, Canada, & Israel

Jose Fernandez

Sales Manager

Mexico, Central, South America,

& The Caribbean

John Buquicchio

General Manager Service & Systems Betterment

Patti Anderson

Spare Parts Manager

Next Steps...

TAPROGGE wrote the book on online Condenser Tube Cleaning and Circulating Cooling Water Debris Filter systems!

Give us a call today for an evaluation of your systems and to learn how we can help you improve the performance of your shell and tube condenser or heat exchanger.